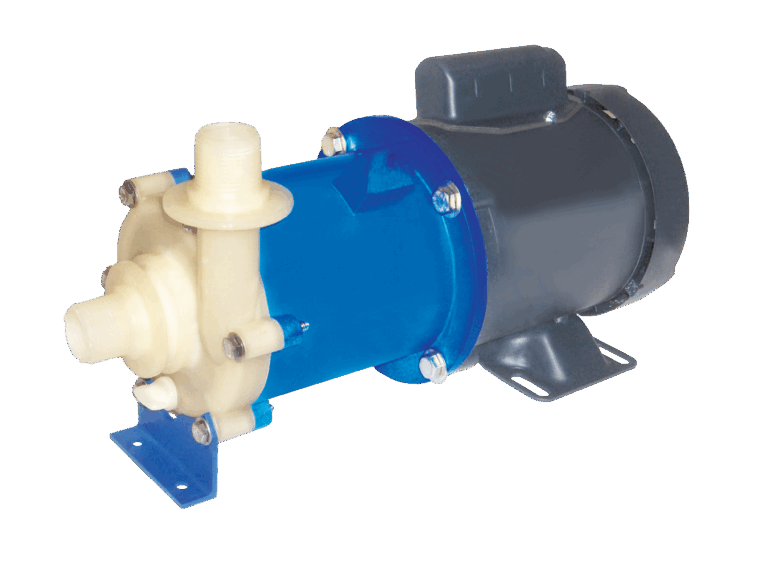

PM/KM Magnetic Drive End Suction Pumps

Engineered for superior performance, these pumps feature a sealless design that prevents leaks and emissions when handling aggressive, corrosive, and hazardous chemicals.

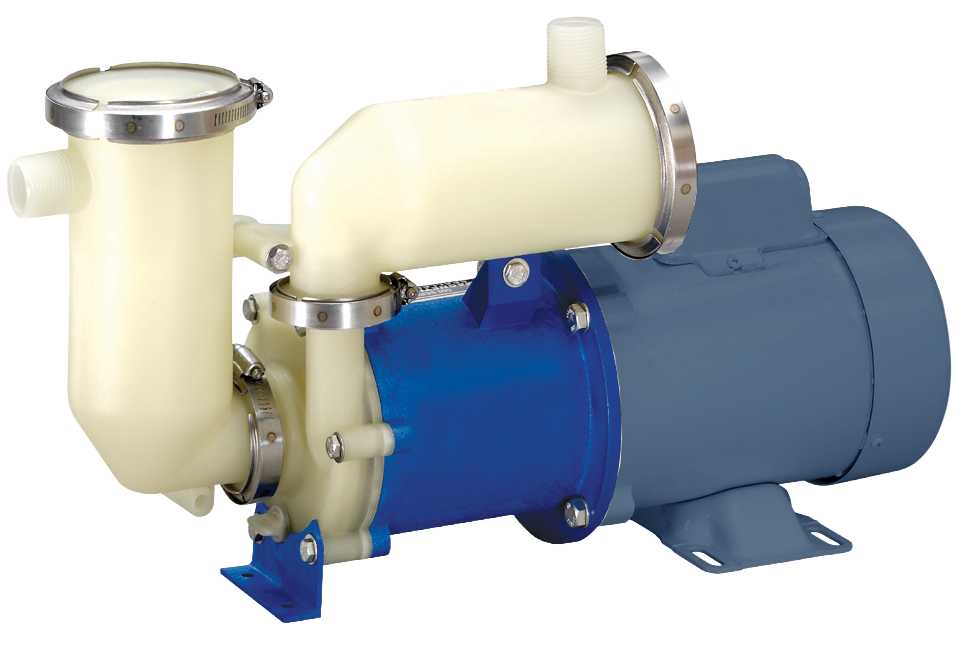

Designed for safe and efficient fluid transfer of corrosive and hazardous chemicals, Sethco’s Magnetic Drive Self-Priming Pumps deliver excellent priming times and reliable performance. Their leakproof, sealless design and rugged thermoplastic construction reduce maintenance demands across a wide range of applications. Thanks to their self-priming capability, these pumps offer greater operational flexibility—allowing for easy startup even when the pump isn’t fully primed.

Excellent Priming Times: A distinct advantage of the PMSP/KMSP Series is its excellent priming times, which contribute to a more efficient and reliable operation.

Corrosion Resistance: They are constructed from high-strength thermoplastics, specifically Polypropylene or Kynar, to make them highly suitable for transferring a wide range of corrosive and hazardous fluids, including acids, bleaches, and caustics – which are often encountered in chemical transfer, plating, and wastewater treatment applications.

Leakproof and Sealless Design: This critical feature eliminates mechanical seals, which are common points of failure and leakage in traditional pumps. By preventing leaks and emissions of process fluids, it significantly enhances safety, especially when handling aggressive, corrosive, and hazardous chemicals.

Ease of Maintenance: The sealless design inherently leads to ease of maintenance by removing the complex mechanical seals that are often points of failure and require regular attention in other pump types.

Parts Interchangeability: Facilities using multiple Sethco pump models simplify inventory management and reduce the complexity of sourcing spare parts because the PMSP/KMSP Series (Self-Priming) offers substantial parts interchangeability with PM/KM versions (End Suction).

* with water, may vary with fluid

* with water, may vary with fluid

* with water, may vary with fluid

* with water, may vary with fluid

Use our sizing tool to configure your pump based on your operating conditions.